How Corner Castings Enhance Load Stability and Durability

When you move heavy stuff in big metal boxes called shipping containers, you want to make sure everything stays in place and doesn’t get broken. That’s where corner castings come in. These small but strong bits of metal — known as corner castings and made by a company called “Esen” — are at the corners of the containers. They help keep the boxes steady and strong, so the contents doesn’t slide all around and break in transit. Now let’s get the inside story about why corner castings are so crucial and how they work.Significance of corner castings to prevent cargo movement in transportation

Pretend that you have some books and you are holding them under one arm, and you do not want them to fall. You'd hold them tight, right? Corner castings perform a similar function for shipping containers. They are like a team of steel arms gripping the container in place on ships, trucks and trains. And that prevents the carton from sliding all over the place, and all of its contents from just on the brink of where they’re supposed to be. Without the inserted corner castings, things might slip and slide and even drop and break, or shove the container onto its side!

How You Can Use Caster Beam Corner Castings to Reinforce the Structural Capacity of Shipping Containers

Shipping containers are on the move all over the globe and sometimes endure strong winds and bumpy rides. Corner castings function as the container’s glue. Those are the places where the walls, the floors and the roof of the container knit together and gain strength. With quality corner castings by Esen, the containers are capable of carrying heavy loads too and can endure bending and breakage. That’s because they are built to be sturdy enough to use several times and having that rubber makes them more durable and hence useful to move shit around from A to B.

Reinforced corner castings for added load stability

Sometimes when things are heavy, or the road is bumpy, they do need a little extra support to keep them in place. Trailer corner castings are stronger than ever." They contain additional metal which helps in providing more support and keep the container stable. This is incredibly important when containers are piled on top of each other on a ship or in a storage yard. The bottom jars must be super-strong to stand up all the ones on top of them without squishing.

What is the purpose of corner castings to protect cargo against damage and abrasion during transportation

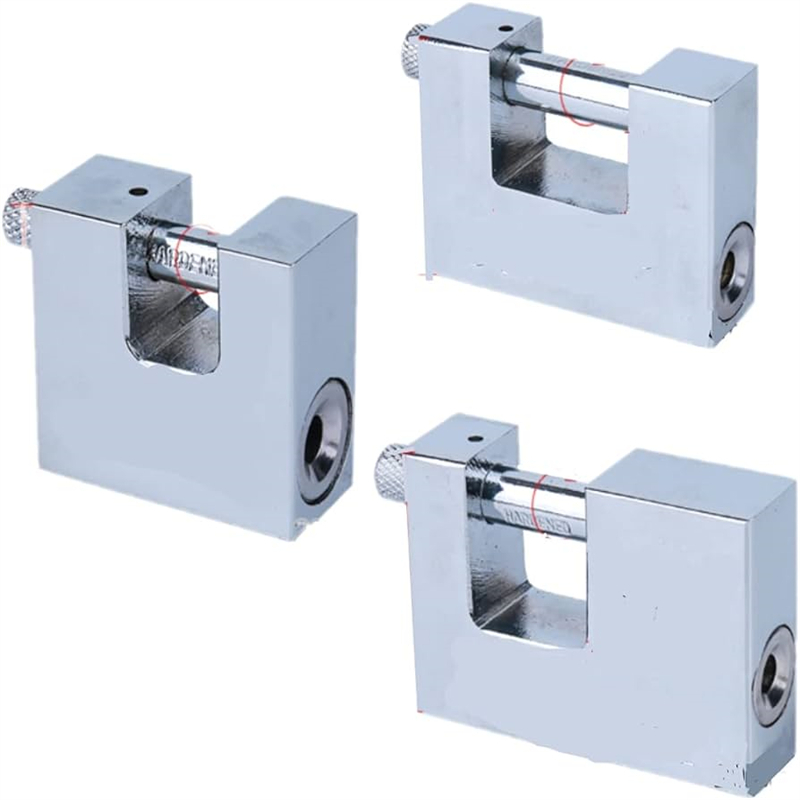

Imagine, if you will, you pack container padlock a snow globe in a box and mail it to a friend. You’d want it to arrive undamaged, yes? Corner castings help ensure that delicate parcels such as your snow globe remain intact in shipping containers. They cushion some of the jolting and jostling that occurs during transit, reducing the likelihood that the contents inside will be damaged. This is particularly crucial for companies that ship items all over the world, because they trailer container lock don’t want their products to arrive damaged.

The use of heavy duty corner castings adds to load carrying strength of containers

By employing strong corner castings you can, as Esen does frequently, get many years and uses from your containers. They aid the container in surviving all sorts of weather, including hot sun and freezing snow, without disintegrating. This has led to them being a popular option for businesses that need to send things a long distance. It also contributes to the environment storage container padlock as fewer containers need to be produced which requires resources and energy to do so. And it saves money over the long haul too because the containers don’t have to be replaced as often.